ATLAS MACHINE wire Saw is a machine for cutting granite cubes and producing different thickness slabs. This machine is designed and manufactured in various sizes to install 20 to 84 diamond wire.

The machine is mounted on four-column structures, which ensures the stability and quality of cutting the stone. The wire is fitted with a diameter of 7.3 to 6.3 mm and each wire in this device is under tension and independent of each other.

Designing this device as a triangular three-roller, causes reducing tension on the cutting wire when working and increases the life of the wire. Also, the ATLAS MACHINE wire saw with a large roller diameter reduces the wire failure on the rollers, which increases the life of the wires.

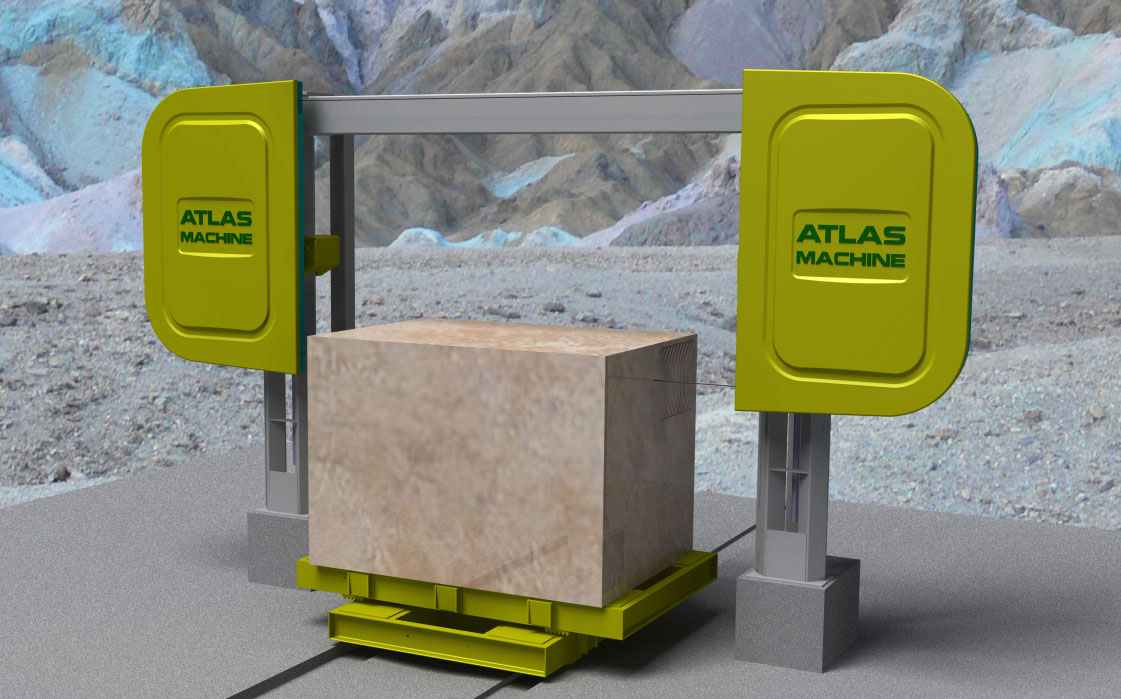

Mono-wire machine

ATLAS MACHINE mono-wires is used to scale the stone block as well as to cut high-thickness stone .In this model, the cutting wire is fixed and with the movement of the block-carrying trolleys, cut the desired dimensions.The block-carrying trolley also has the ability to rotate, which is used to cut other stones.

The ATLAS MACHINE mono-wire is made of two strong bases that are joined to a metal structure. The ATLAS MACHINE mono-wire has 4 poles with a diameter of 1000 mm. The diameter of the wire is 7.3 mm. The length of the cutting wire is 1830 cm.

Orbital polishing slab

Due to the competitive conditions of the market for manufacturers, in order to produce higher quality stone and also more production, ATLAS MACHINE Company designs and produces the latest orbital polishing-slab technology used for granite and marble.

In commonly used polishing-slabs, all the spindles are placed on a bridge, thus creating limits for rubbing the stones with irregular geometric shapes, and for polishing the stones, abrasive plate should be lifted from the stone and upon returning the bridge, it should be drop again on the stone, causing the device to become uneven.

In an orbital polishing-orbital device, each spindle is mounted on a separate structure and has a separate motion than the other spindles. Therefore, the contact of the abrasive plate on the stone is continuous at the time of polishing and until the stone is under the spindle, the abrasive is not cut off from the stone, which increases the speed and quality and gloss of the produced stone.

In addition to the transverse motion of the spindles, this device also has a longitudinal motion, which performs the operation of the device in a similar way to the hand-held instrumentation, which improves the quality and characteristics of the stone.