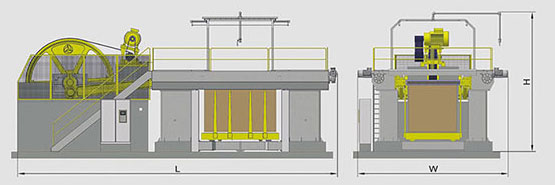

The ATLAS gang saw has been designed for cutting Marble. This machine has excellent performance in cutting speed and quality due to the movement of the frame supporting the blades on four linear guides with hydro static lubrication.

ATLAS Gang Saw

Projects

Features

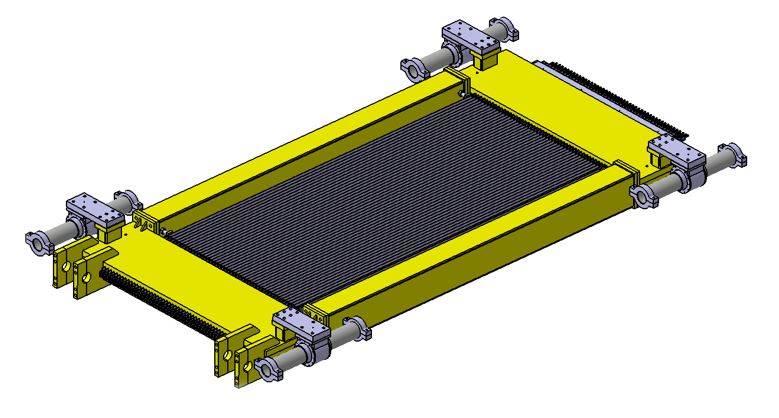

Design features and characteristics of the device:

- Flywheel with a diameter of 3.5 m and a weight of 8500 kg to create uniform motion and provide the necessary energy for cutting

- Shatton made of casting steel, resistant to impact and machined with the highest accuracy

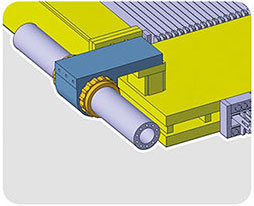

- Making guide bushes made of phosphor bronze anti-abrasion

- The main shaft of the device is made of forged steel with high resistance to dynamic loads

- Perform ultrasonic testing on the main shaft to ensure its surface quality and prevent the growth of fine cracks after turning

- Accurate calculation, analysis and engineering selection of all parts of the machine in order to have enough strength and long life

- The highest precision in machining parts and structures of the device for its high performance and long service life

- Three-layer epoxy paint coating with paint spray equipment

- Purchase of standard parts including bearings, belts, bearings and …from reputable European brands.

- PLC Power Switch with the most comprehensive control equipment and HMI display

- Startup of the engine as software starter to prevent demand plant increase, reduce power consumption at startup and protect the main engine

- The ability to enter the stone block from the front and side of the device

- Automatic lubrication of the machine’s main screws and fixed and pressure sliders

- Delivery of two trolleys with the device

The characteristic feature of this type of gang saw is the frame’s movement of the retaining blades onto the hydrostatic linear guides, which has the following advantages:

- Create the lowest vibration at high speeds than the same device

- Inhibition of various forces caused by cutting the stone and creating a uniform surface when cutting slabs

- The same thickness at the beginning and end of the cutting

- decreasing the depreciation and increasing life of the device

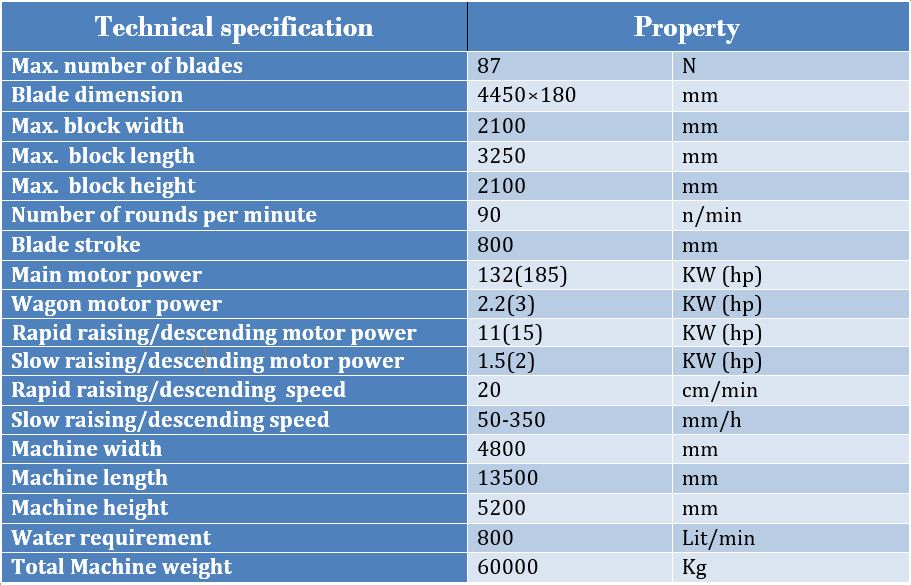

Technical specification